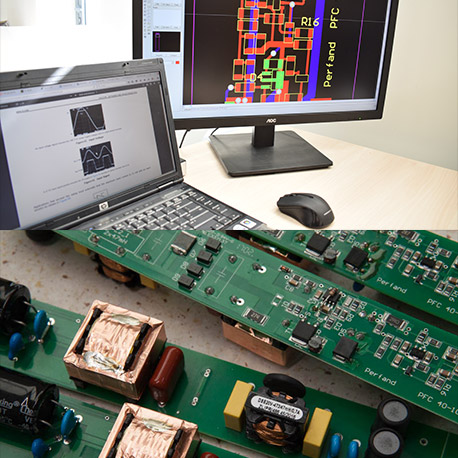

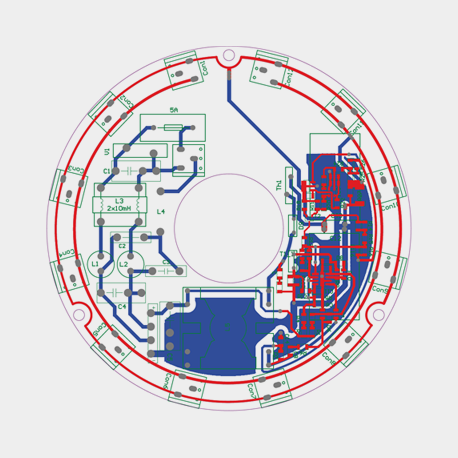

The founder and owner of the company is Andrzej Trawiński. Thanks to a comprehensive approach, the manufacturing process of LED luminaires includes electronic design and production (printed circuits with led diodes, power supplies) - production of lighting fixtures (production is based on own technical know-how)

in addition to modern design they also stand out with energy efficiency - with very low power consumption they emit very large amounts of light (up to 200 lm / W). Thanks to this, you can save money and be more ECO.

So that you can be longer ECO, we give you a 5-year warranty.

We protect our ideas thus creating our own know-how. The fittings produced in Perfand LED are reserved in the Patent Office in order to ensure their uniqueness.

We protect our ideas thus creating our own know-how. The fittings produced in Perfand LED are reserved in the Patent Office in order to ensure their uniqueness.

Speed is our asset. We make every effort to ensure that orders are processed in the shortest time possible .

We cooperate with the Institute of Plant Physiology at the Polish Academy of Sciences in terms of patented luminaires for applications in plant growing.

The most important factor in Perfand Led is people. Specialist staff: engineers, designers, electronic engineers and electricians, each day thanks to the use of the latest technologies and knowledge, participate in creating unique lighting fixtures with extremely high functional parameters adapted to the requirements of individual clients and industries. The staff is the foundation of our company and give you trust and satisfaction.

The success of our solutions is also based on the power supplies of our construction. In our LED factory’s laboratory each newly created product is thoroughly tested, because, apart from high quality, our priority is to ensure safety in the usage of lighting fixtures. Experience and reliability in adapting to the requirements of EU directives is the foundation for any project that is being developed at Perfand LED.

All projects are carried out by highly qualified specialists who have wide experience in designing a variety of electronic circuits and printed circuits. The design of each LED luminaire is subjected to a series of temperature tests so that the level of heat dissipation is as high as possible. As we mentioned, the life of LEDs is determined by the temperature, which is why we pay so much attention to it.

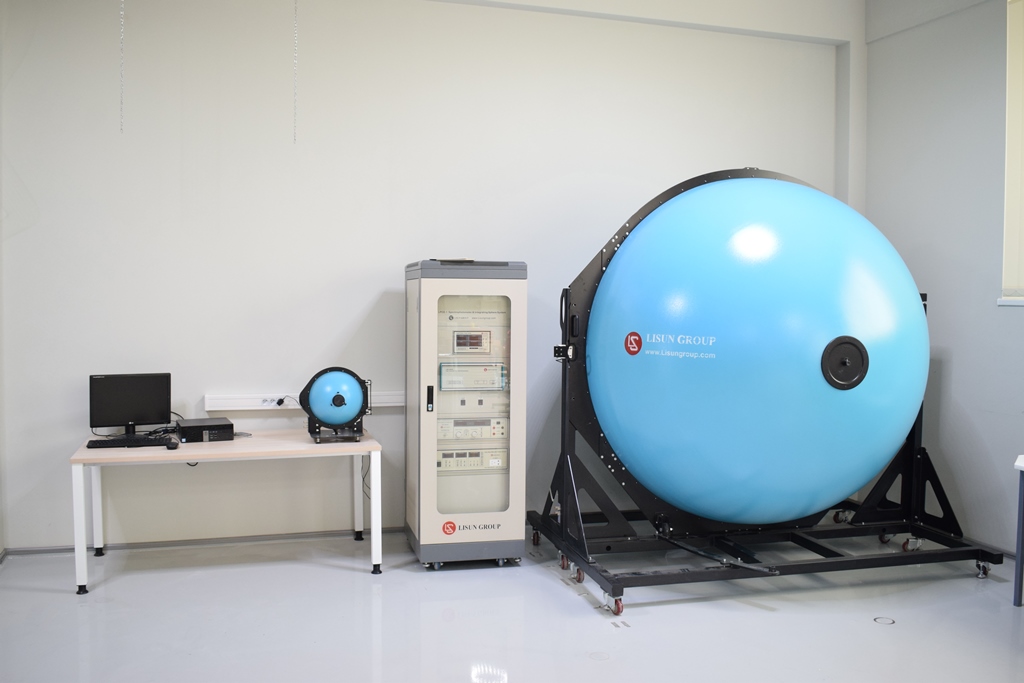

Each newly created product is thoroughly tested in terms of safety according to the requirements of EU directives. Extremely high technical parameters of our LED luminaires are confirmed by external factors. Everything for you and for the protection of the natural environment.

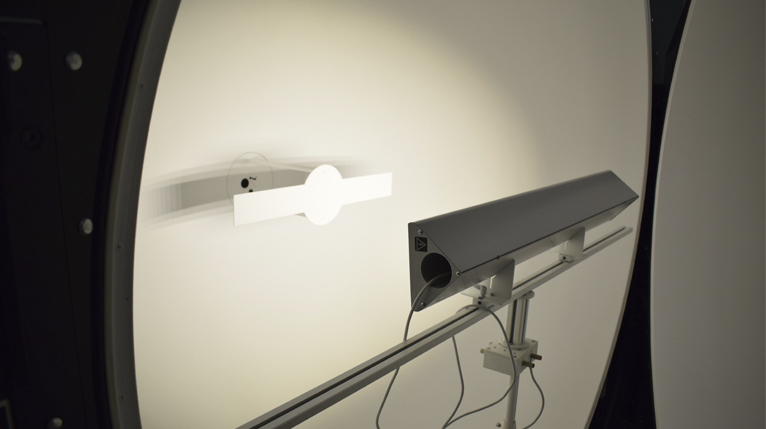

Our latest designs are always thoroughly researched, from prototype to finished product. In tests, we use modern equipment for electrical and photometric measurements: a spectrophotometer, a photometric sphere and standardized lux meters. In order to ensure safety, we use thermal imaging cameras to evaluate the temperature of the fixtures and the designed electronic circuits.

Our CSR is carried out in areas related to employees, suppliers, customers, local community and environmental protection. Within the company, we apply the principles of mutual relations and cooperation between employees. These rules are included in the relevant company documents. We constantly conduct activities aimed at supporting the local community and sport-related initiatives in rural areas. We also conduct educational activities regarding environmental protection and the use of modern technologies in the field of lighting (conferences, meetings).